GIICL型鼓形齿式联轴器

鼓型齿式联轴器属于刚挠性联轴器,具有径向、轴向和角向等轴线偏差补偿能力,与直齿式联轴器相比,具有结构紧凑、回转半径小、承载能力大、传动效率高、噪声低及维修周期长等优点。

所属分类

详细介绍

产品特点

鼓型齿式联轴器属于刚挠性联轴器,具有径向、轴向和角向等轴线偏差补偿能力,与直齿式联轴器相比,具有结构紧凑、回转半径小、承载能力大、传动效率高、噪声低及维修周期长等优点。

应用场合

适用于冶金、矿山、起重运输等行业、也适用于石油、化工、通用机械等各类机械的轴系传动。

GIICL型鼓形齿式联轴器

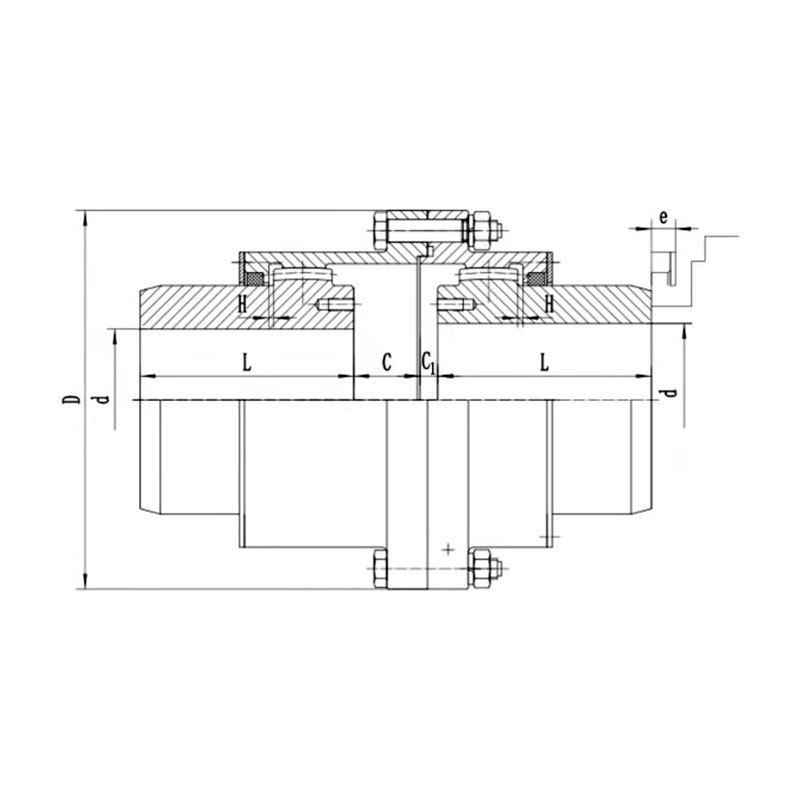

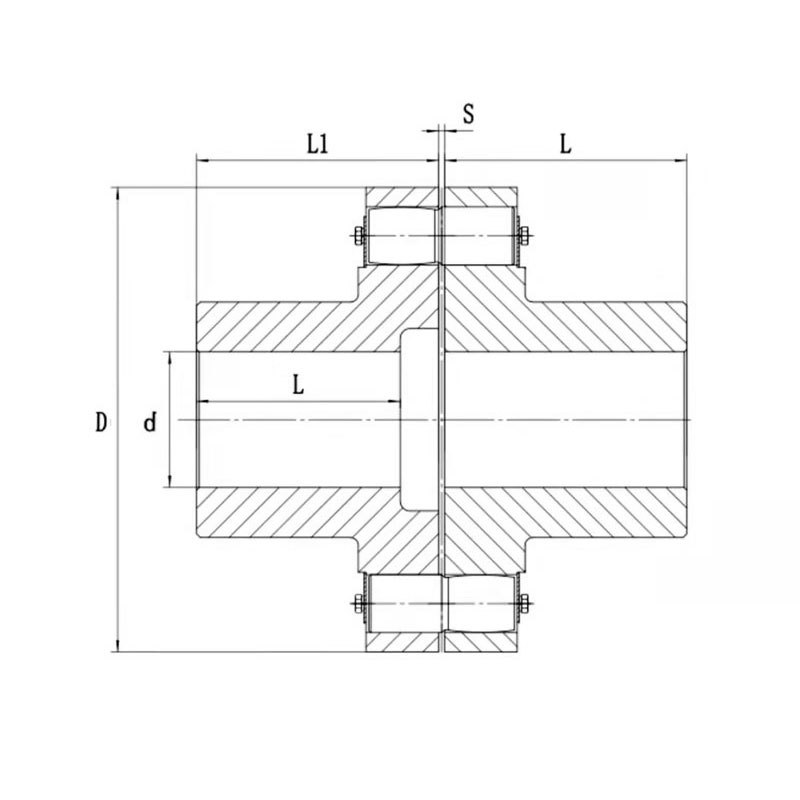

GIICL型基本型(窄型)鼓形齿式联轴器齿间距小,允许相对径向位移小,结构紧凑,转动惯量小,适用于公称转矩0.4~4500kN.m联接水平两同轴线轴系传动,工作环境温度-20~+80℃。结构型式见图4.2和图4.3,技术参数和主要尺寸见表4-2。

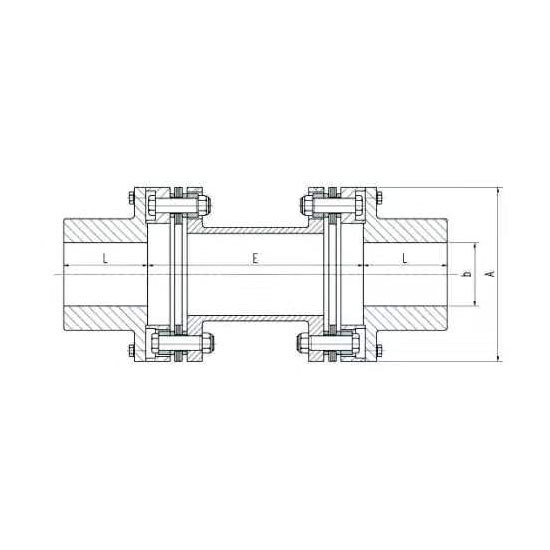

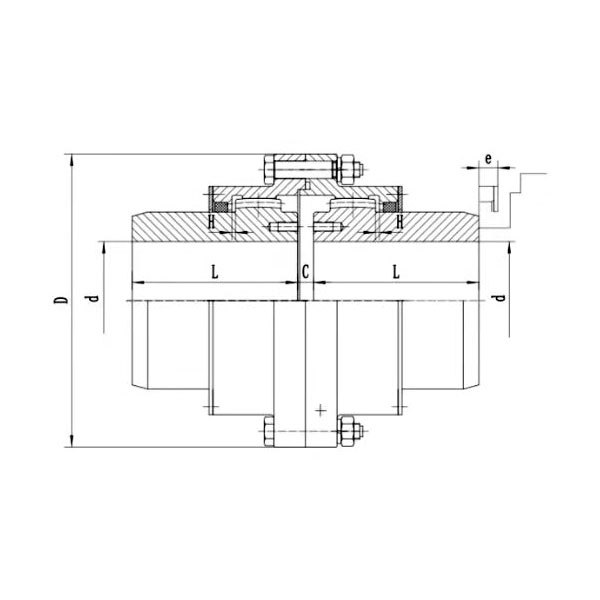

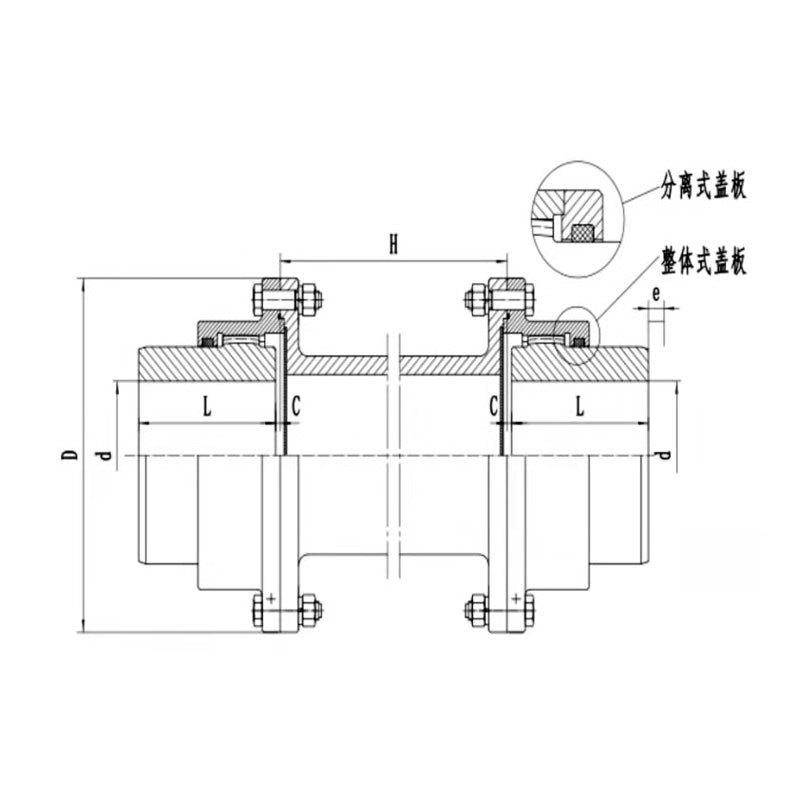

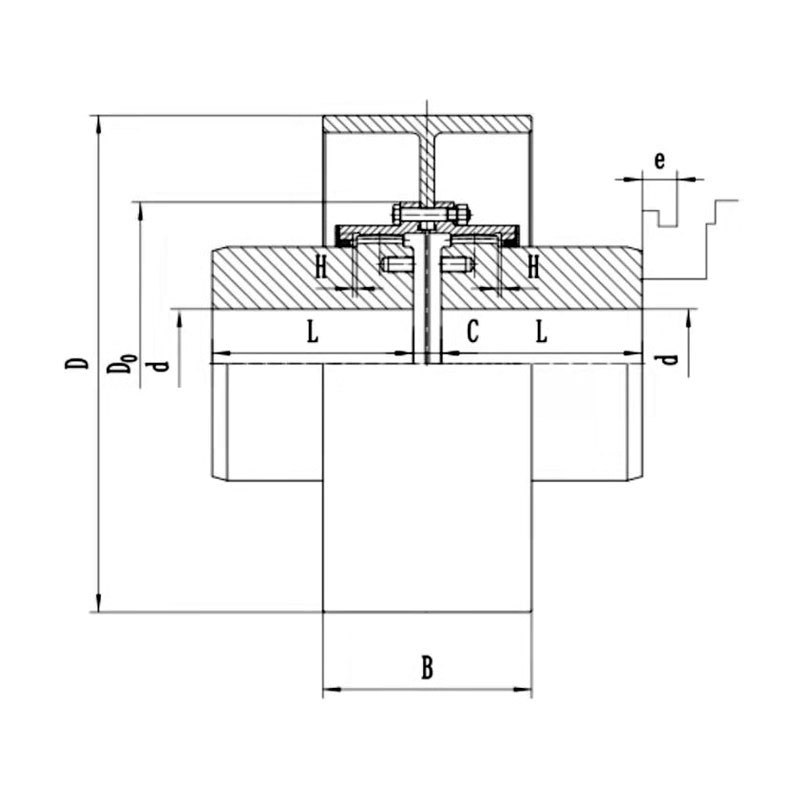

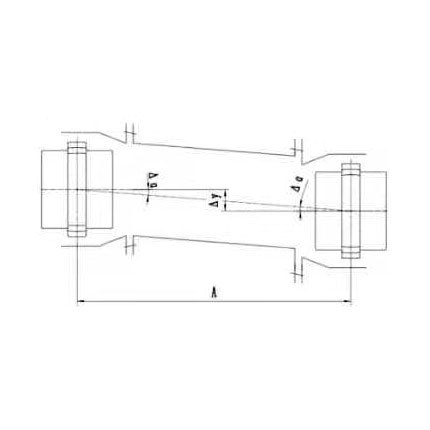

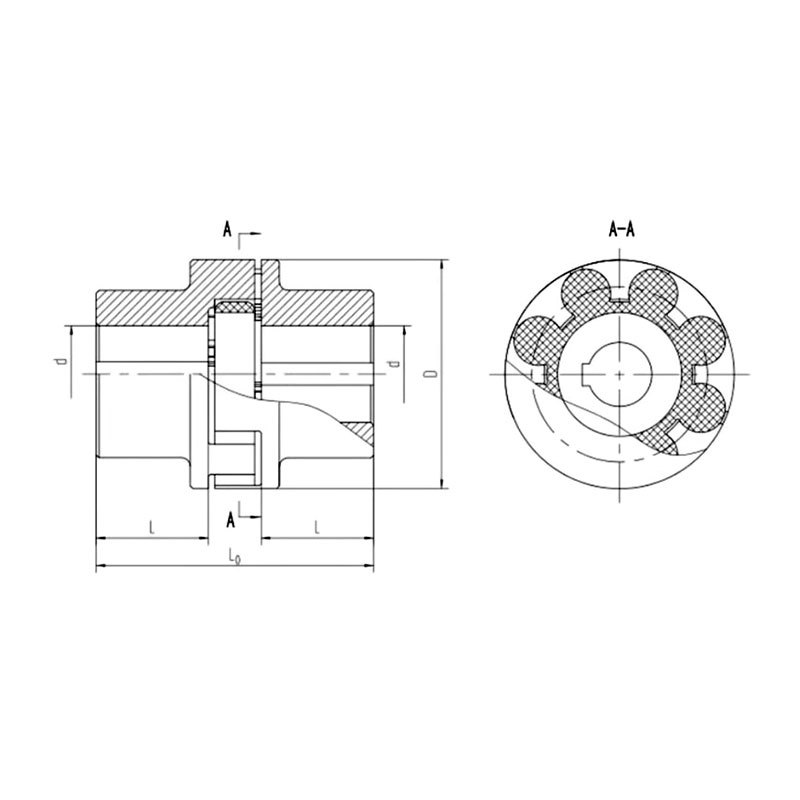

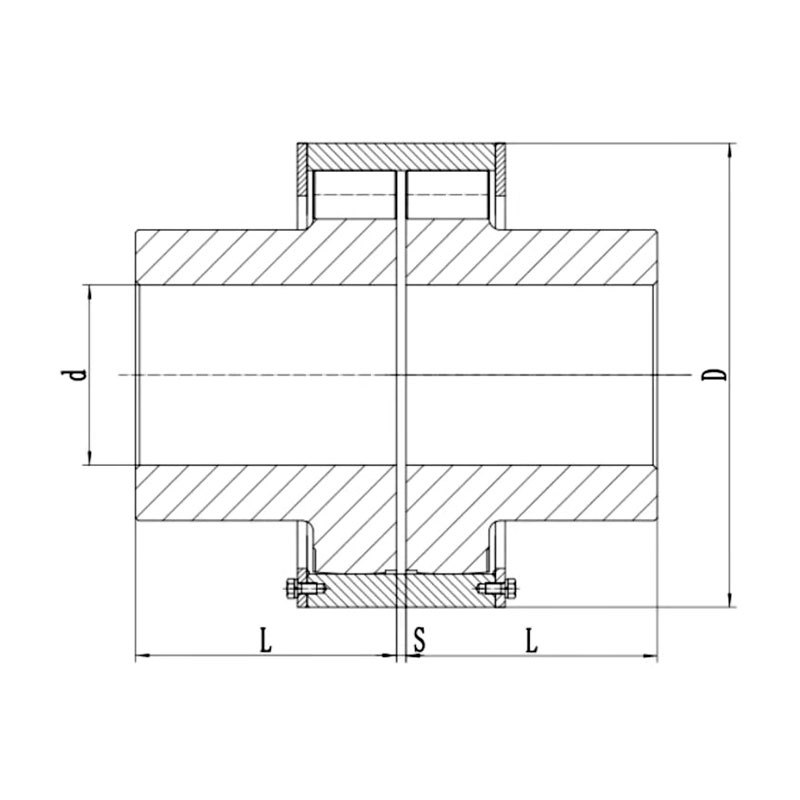

图4.2 GIICL1-GIICL13型鼓形齿式联轴器

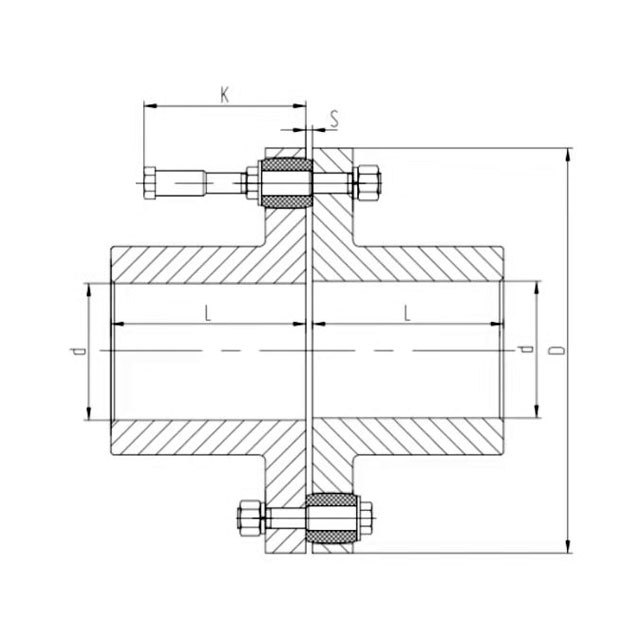

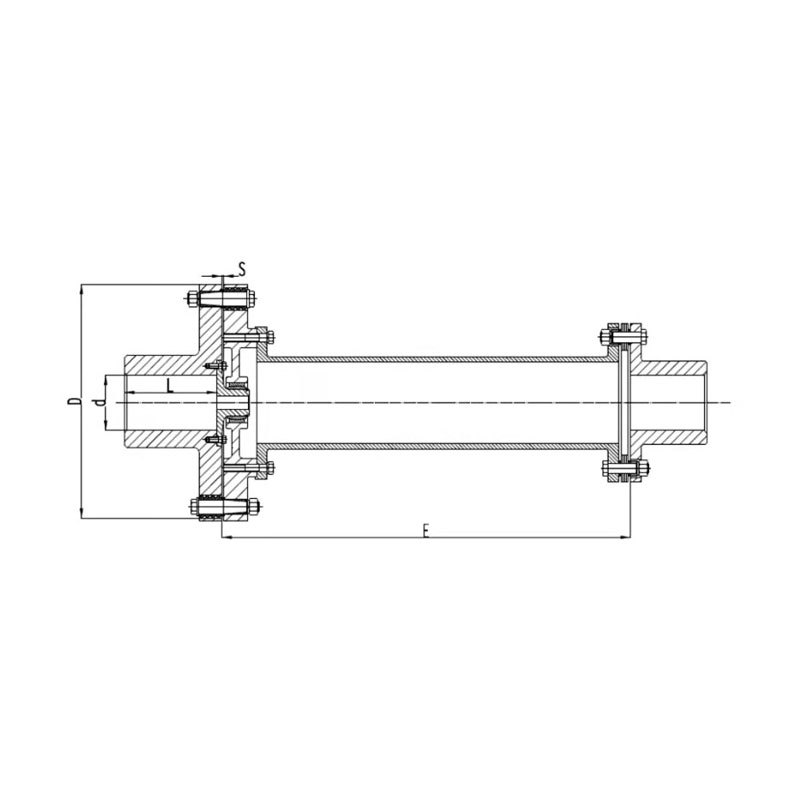

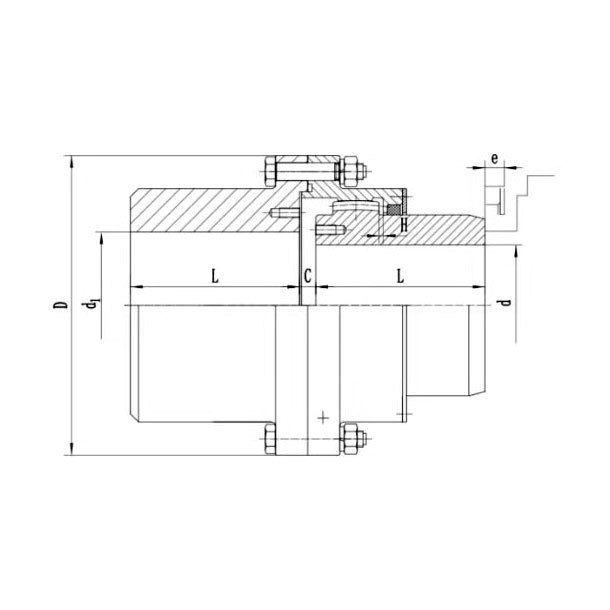

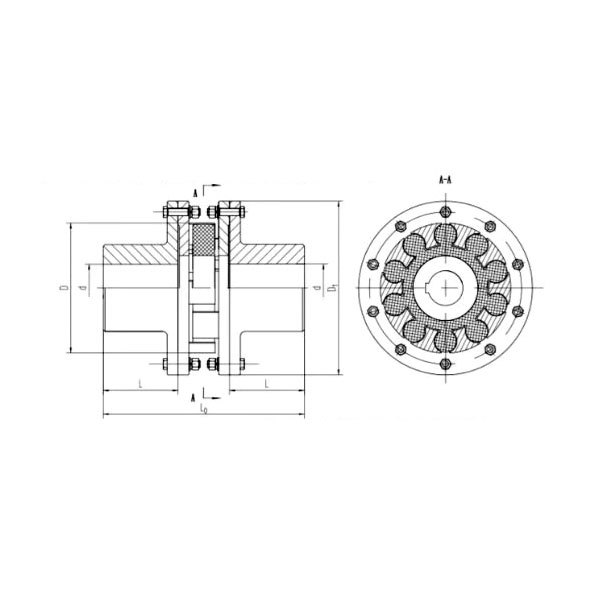

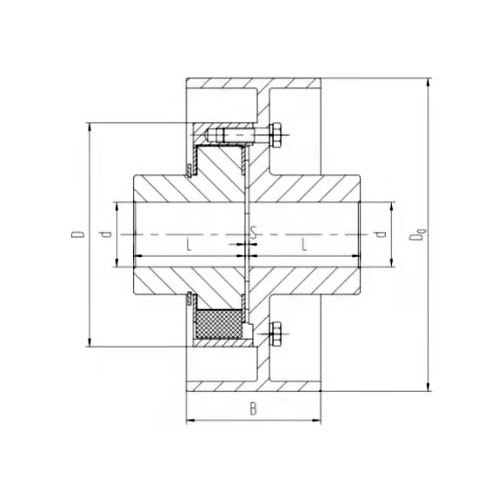

图4.3 GIICL14-GIICL25型鼓形齿式联轴

表4-2 GIICL型鼓形齿式联轴器技术参数和主要尺寸

| 型号 | 公称转矩 Tn KN · m |

许用转速 [n] r/min |

轴孔直径 | 轴孔长度L | D | C | H | e | 转动惯量 Kg · ㎡ |

润滑脂用量 mL |

质量 Kg |

|

| d | Y | J1 | ||||||||||

| mm | ||||||||||||

| GIICL1 | 0.4 | 4000 | 16,18,19 | 42 | - | 103 | 8 | 2 | 38 | 0.0035 | 51 | 5.1 |

| 20,22.24 | 52 | 38 | 0.0035 | 3 | ||||||||

| 25,28 | 62 | 44 | 0.0035 | 3.1 | ||||||||

| 30,32,35 | 82 | 60 | 0.00375 | 3.6 | ||||||||

| GIICL2 | 0.71 | 4000 | 20,22,24 | 52 | - | 115 | 8 | 2 | 42 | 0.00575 | 70 | 4.9 |

| 25.28 | 62 | 44 | 0.00550 | 4.5 | ||||||||

| 30,32,35,38 | 82 | 60 | 0.006 | 5.1 | ||||||||

| 40,42,45 | 112 | 84 | 0.00675 | 6.2 | ||||||||

| GIICL3 | 1.12 | 4000 | 22,24 | 52 | - | 127 | 8 | 2 | 42 | 0.0105 | 68 | 7.5 |

| 25,.28 | 62 | 44 | 0.010 | 7 | ||||||||

| 30,32,35,38 | 82 | 60 | 0.010 | 6.9 | ||||||||

| 40,42,45,48,50,55,56 | 112 | 84 | 0.0113 | 8.6 | ||||||||

| GIICL4 | 1.8 | 4000 | 38 | 82 | 60 | 149 | 8 | 2 | 42 | 0.02 | 87 | 10.1 |

| 40,42,45,48,50,55,56 | 112 | 84 | 0.0223 | 12.2 | ||||||||

| 60,63,65 | 142 | 107 | 0.0245 | 14.5 | ||||||||

| GIICL5 | 3.15 | 4000 | 40,42,45,48,50,55,56 | 112 | 84 | 167 | 10 | 2.5 | 42 | 0.0378 | 125 | 16.4 |

| 60,63.65,70,71,75 | 142 | 107 | 0.0433 | 19.6 | ||||||||

| GIICL6 | 5 | 4000 | 45,48,50,55,56 | 112 | 84 | 187 | 10 | 2.5 | 42 | 0.0663 | 148 | 22.1 |

| 60,63,65,70,71,75 | 142 | 107 | 0.075 | 26.5 | ||||||||

| 80,85,90 | 172 | 132 | 0.0843 | 31.2 | ||||||||

| GIICL7 | 7.1 | 3750 | 50.55.56 | 112 | 84 | 204 | 10 | 2.5 | 42 | 0.103 | 175 | 27.6 |

| 60, 63, 65, 70,71,75 | 142 | 107 | 0.115 | 33.1 | ||||||||

| 80,85,90,95 | 172 | 132 | 0.1298 | 39.2 | ||||||||

| 100,105 | 212 | 167 | 0.151 | 47.5 | ||||||||

| GIICL8 | 10 | 3300 | 55,56 | 112 | 84 | 230 | 12 | 3 | 147 | 0.167 | 268 | 35.5 |

| 60, 63,65,70,71,75 | 142 | 107 | 0.188 | 42.3 | ||||||||

| 80,85,90,95 | 172 | 132 | 0.210 | 49.7 | ||||||||

| 100,110,115 | 212 | 167 | 0.241 | 60.2 | ||||||||

| GIICL9 | 16 | 3000 | 60,63,65,70,71,75 | 142 | 107 | 256 | 12 | 3 | 47 | 0.316 | 310 | 55.6 |

| 80,85,90,95 | 172 | 132 | 0.356 | 65.6 | ||||||||

| 100,110,120,125 | 212 | 167 | 0.413 | 79.6 | ||||||||

| 130,135 | 252 | 202 | 0.470 | 95.8 | ||||||||

表4-2 GIICL型鼓形齿式联轴器技术参数和主要尺寸

| 型号 | 公称转矩 Tn KN · m |

许用转速 [n] r/min |

轴孔直径 | 轴孔长度L | D | C | H | e | 转动惯量 Kg · ㎡ |

润滑脂用量 mL |

质量 Kg |

|

| d | Y | J1 | ||||||||||

| mm | ||||||||||||

| GIICL10 | 22.4 | 2650 | 65,70,71,75 | 142 | 107 | 287 | 14 | 3.5 | 47 | 0.511 | 472 | 72 |

| 80,85,90,95 | 172 | 132 | 0.573 | 84.4 | ||||||||

| 100,110,120,125 | 212 | 167 | 0.659 | 101 | ||||||||

| 130,140,150 | 252 | 202 | 0.745 | 119 | ||||||||

| GIICL11 | 35.5 | 2350 | 70,71,75 | 142 | 107 | 352 | 14 | 3.5 | 47 | 1.454 | 550 | 97 |

| 80,85,90,95 | 172 | 132 | 1.096 | 114 | ||||||||

| 100,110,120,125 | 212 | 167 | 1.235 | 138 | ||||||||

| 130,140,150 | 252 | 202 | 1.340 | 161 | ||||||||

| 160,170,175 | 302 | 242 | 1.588 | 189 | ||||||||

| GIICL12 | 50 | 2100 | 75 | 142 | 107 | 362 | 16 | 4 | 49 | 1.623 | 695 | 128 |

| 80,85,90,95 | 172 | 132 | 1.828 | 150 | ||||||||

| 100,110,120,125 | 212 | 167 | 2.113 | 205 | ||||||||

| 130,140,150 | 252 | 202 | 2.40 | 213 | ||||||||

| 160,170,180 | 302 | 242 | 2.728 | 248 | ||||||||

| 19,200 | 352 | 282 | 3.055 | 285 | ||||||||

| GIICL13 | 71 | 1850 | 150 | 252 | 202 | 412 | 18 | 4.5 | 49 | 3.925 | 1019 | 269 |

| 160,170,180,185 | 302 | 242 | 4.425 | 315 | ||||||||

| 190,200.220.225 | 352 | 282 | 4.918 | 360 | ||||||||

| GIICL14 | 112 | 1650 | 170,180,185 | 302 | 242 | 462 | 22 | 5.5 | 63 | 8.025 | 3900 | 421 |

| 190,200,220 | 352 | 282 | 8.8 | 476 | ||||||||

| 240,250 | 410 | 330 | 9.725 | 544 | ||||||||

| GIICL15 | 180 | 1500 | 190,200,220 | 352 | 282 | 512 | 22 | 5.5 | 63 | 14.300 | 3700 | 608 |

| 240,250,260 | 410 | 330 | 15.850 | 696 | ||||||||

| 280,285 | 470 | 380 | 17.45 | 786 | ||||||||

| GIICL16 | 250 | 1300 | 220 | 352 | 282 | 580 | 28 | 7 | 67 | 23.925 | 4500 | 799 |

| 240,250,260 | 410 | 330 | 26.45 | 913 | ||||||||

| 280,300,320 | 470 | 380 | 29.1 | 1027 | ||||||||

| GIICL17 | 355 | 1200 | 250,260 | 410 | 330 | 644 | 28 | 7 | 67 | 43.095 | 4900 | 1176 |

| 280,290,300,320 | 470 | 380 | 47.525 | 1322 | ||||||||

| 340,360,365 | 550 | 450 | 53.725 | 1532 | ||||||||

表4-2 GIICL型鼓形齿式联轴器技术参数和主要尺寸

| 型号 | 公称转矩 Tn KN · m |

许用转速 [n] r/min |

轴孔直径 | 轴孔长度L | D | C | H | e | 转动惯量 Kg · ㎡ |

润滑脂用量 mL |

质量 Kg |

|

| d | Y | J1 | ||||||||||

| mm | ||||||||||||

| GIICL18 | 500 | 1050 | 280,295,300,320 | 470 | 380 | 726 | 28 | 8 | 75 | 78.525 | 7000 | 1698 |

| 340,360,380 | 550 | 450 | 87.75 | 1948 | ||||||||

| 400 | 650 | 540 | 99.50 | 2278 | ||||||||

| GIICL19 | 710 | 950 | 300,320 | 470 | 380 | 818 | 32 | 8 | 75 | 136.75 | 8900 | 2249 |

| 340,350,360,380,390 | 550 | 450 | 153.75 | 2591 | ||||||||

| 400.420,440,450.460.470 | 650 | 540 | 175.5 | 3026 | ||||||||

| GIICL20 | 1000 | 800 | 360,380,390 | 550 | 450 | 928 | 32 | 10.5 | 75 | 261.75 | 11000 | 3384 |

| 400,420,440,450,460,480,500 | 650 | 540 | 299 | 3984 | ||||||||

| 530,540 | 800 | 680 | 360.75 | 4430 | ||||||||

| GIICL21 | 1400 | 750 | 400,420,440,450,460,480,500 | 650 | 540 | 1022 | 40 | 11.5 | 75 | 468.75 | 13000 | 4977 |

| 530,560,600 | 800 | 680 | 561.50 | 6152 | ||||||||

| GIICL22 | 1800 | 650 | 450,460,480,500 | 650 | 540 | 1134 | 40 | 13 | 75 | 753.75 | 16000 | 6318 |

| 530,560,600,630 | 800 | 680 | 904.75 | 7738 | ||||||||

| 670,680 | 900 | 780 | ||||||||||

| GIICL23 | 2500 | 600 | 530,560,600,630 | 800 | 680 | 1282 | 50 | 14.5 | 80 | 1517 | 28000 | 10013 |

| 670,700,710,750,770 | 900 | 780 | 1725 | 11553 | ||||||||

| GIICL24 | 3550 | 550 | 560,600,630 | 800 | 680 | 1428 | 50 | 16.5 | 80 | 2486 | 33000 | 12915 |

| 670,700,710,750 | 900 | 780 | 2838.5 | 15015 | ||||||||

| 800,850 | 1000 | 880 | 3131.75 | 16615 | ||||||||

| GIICL25 | 4500 | 460 | 670,700,710,750 | 900 | 780 | 1644 | 50 | 19 | 80 | 5174.25 | 43000 | 19837 |

| 800,850 | 1000 | 880 | 5836.5 | 22381 | ||||||||

| 900,950 | - | 980 | 6413 | 24765 | ||||||||

| 1000,1040 | - | 1100 | 7198.25 | 27797 | ||||||||

注:1.转动惯量与质量按J1型计算,并包括轴伸在内。

2.轴孔长度推荐J1型。

3.e为更换密封所需要的尺寸。

4.许用转速[n]为当量角向偏移量≤0.25°时的值,若当量角向偏移量>0.25o时,选型请咨询我公司技术人员。

关键词

在线咨询

立即联系我们,获取免费的专家咨询服务!

相关产品